When you mainly want to design new things, experiment, and measure, soldering hundreds of components is not the most interesting thing to do. Therefore, somewhere in last autumn I decided I will build a reflow oven. I ordered a Controleo3 kit but it took a couple of months to actually start it, and even building took serious amount of time. Anyway, I did it on my Christmas holidays. I shot videos as well and these have been ready for a while already and now finally posted.

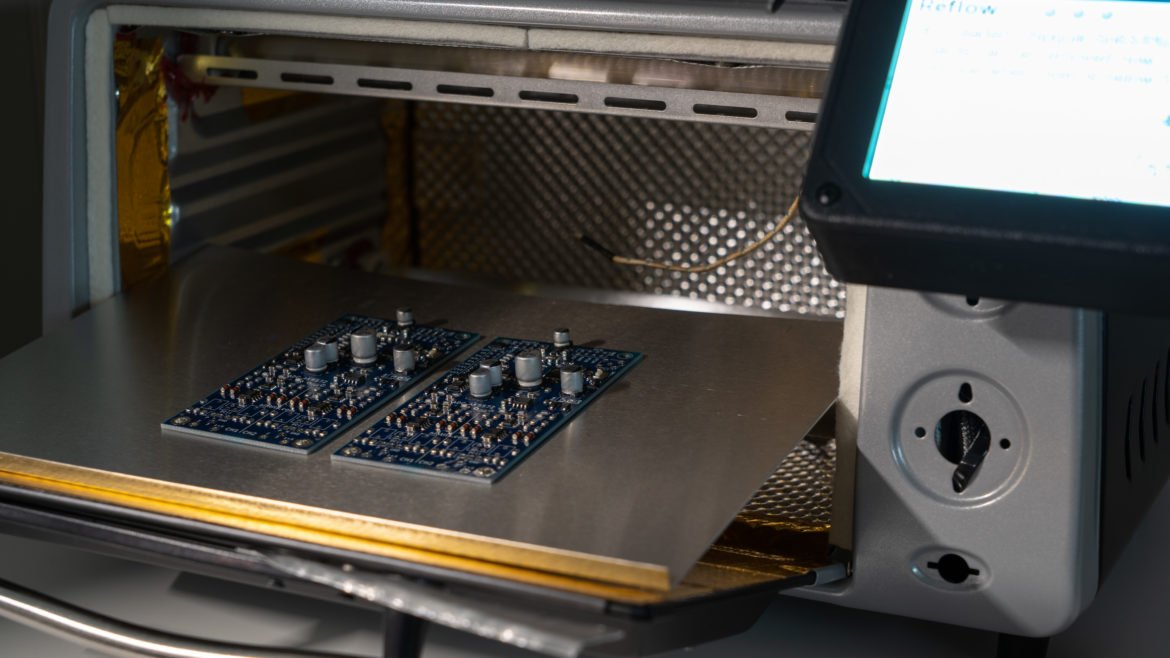

I will still build prototypes completely by hand but this oven helps building small batches of boards for sale. Pick and place is still manual and not enjoyable though! For example, ADC AK5572 has almost 150 components onboard and if you build a batch of 10 like I did one Sunday, that is a full day job even with this oven. So next I need a pick and place machine….

Below the photo gallery there are two videos, the first one introducing the oven and showing how it was build. It’s mostly voice-over video done after it was built, going through photos and clips taken during building process. The second video is about trial reflow runs. Note that I didn’t know anything about reflowing before building this. I had never even used solder paste (except syringe recently) or stencils.

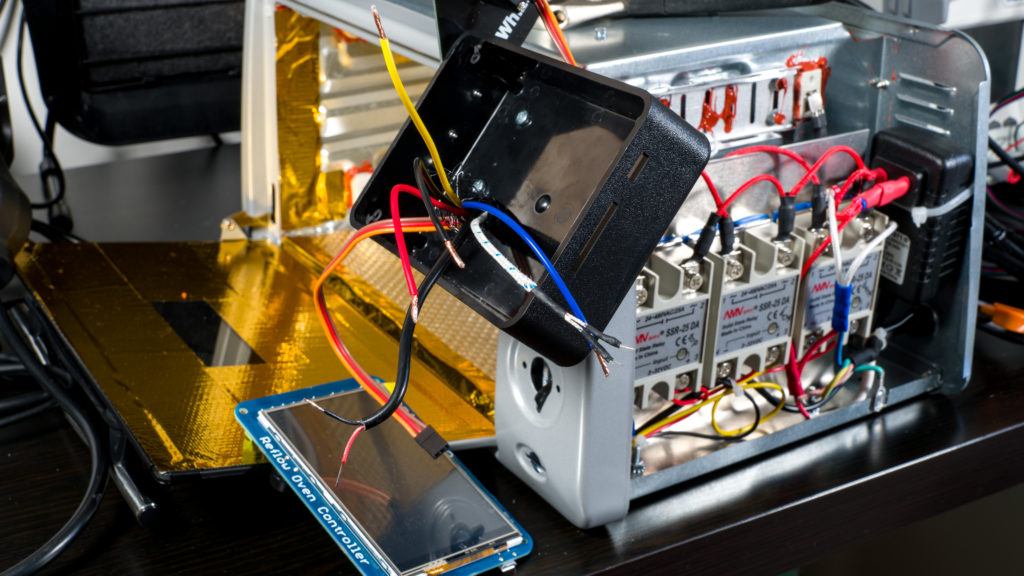

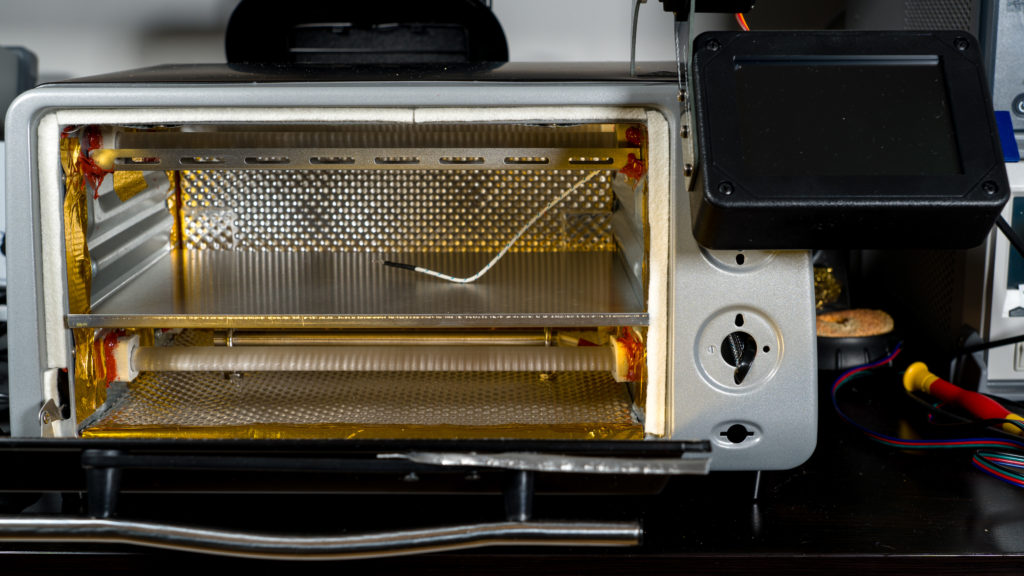

The oven I used was 9L Netta oven from Amazon UK (two of them to get enough heating power) and Controleo3 kit was from Whizoo. The kit includes almost everything you need for building and has good attention to details. The instructions in Whizoo website are superb which is largely why I chose Controleo. There is a lot to read but if you are planning to build an oven, main things you want from your oven is small size, lots of heating power (per volume), and good thermal insulation. And a capable controller of course. For example, I have over 2 kW of heating power in the 9L oven. In a ready-made commercial oven you can likely only meet the small size so you need to work out the rest. Building (without proper tooling for metal) was not so enjoyable but it was worth it.